IITGN, JAIST develop material for faster charging of laptops, mobiles

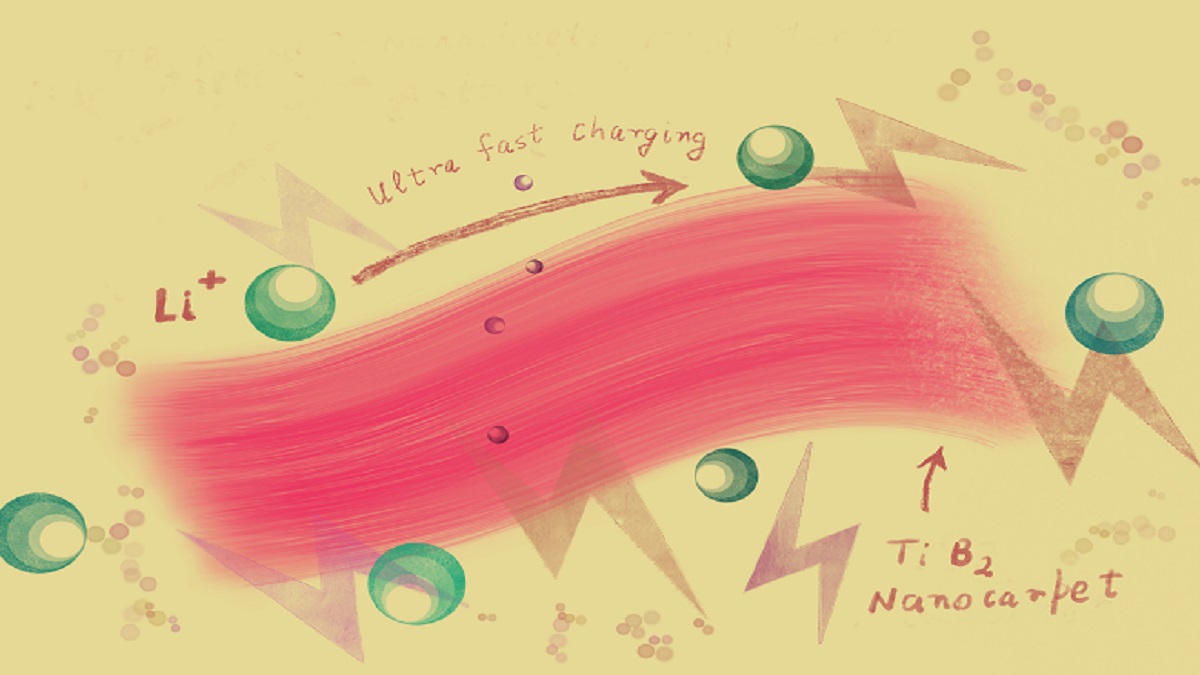

The two-dimensional anode material has been developed using nanosheets derived from titanium diboride (TiB2), a material that resembles a multi-stacked sandwich, where metal atoms are present in-between layers of boron.

A team of researchers from Indian Institute of Technology, Gandhinagar (IITGN) in collaboration with Japan Advanced Institute of Science and Technology (JAIST) has invented a new anode material that leads to lithium-ion batteries (LIBs) to be recharged within minutes.

The two-dimensional anode material has been developed using nanosheets derived from titanium diboride (TiB2), a material that resembles a multi-stacked sandwich, where metal atoms are present in-between layers of boron. Currently, graphite and lithium titanate are among the most widely used anode materials in the commercially available lithium-ion batteries (LIBs) that power laptops, mobile phones, and electric vehicles.

What is anode material?

Anode material is the negative electrode in lithium-ion batteries and are paired with cathode material in a lithium-ion battery cell. The anode materials in lithium-ion cells act as the host where they reversibly allow lithium-ion intercalation / deintercalation during charge or discharge cycles. The research teams aimed to develop a material for anode that not only enables fast charging of the battery but should also facilitate a long life.

Key features of anode material

- Ultra-fast charging time (full charge within minutes)

- Long life cycle (10,000 cycles at high charge currents).

- The nanosheets that are used to prepare anode have a high density of pores. While the planar nature and chemistry of nanosheets provide a high surface area for catching hold of Li-ions, the pores enable a better diffusion of ions.

The research team led by Kabeer Jasuja (IITGN) and Noriyoshi Matsumi (JAIST) found that that this anode had an ultra-fast charging capacity with a considerable discharge capacity at high-capacity retention (up to 80 per cent even after 10,000 cycles of operation), which means that batteries made with this material would give almost the same high performance even after more than 10,000 cycles of charging.

The researchers emphasised that this is technology can be used for commercial applications where high energy density, high power, long life, and ultra-fast charging are required. The research team plans to translate this work from the lab to a real-life application.

Professor Noriyoshi Matsumi, JAIST, said, “Nowadays, the requirement for high-rate charge-discharge technology is tremendously increasing in order to enable widespread commercialisation of various kinds of electric vehicles in future. Our findings can stimulate related research fields to invite more researchers to work on application of the unique 2D materials. We hope continuous research will contribute to the convenience of EV users, lesser air pollution on the road, especially in cities, and less stressful mobile life, which will enhance the productivity of society.”

Follow Shiksha.com for latest education news in detail on Exam Results, Dates, Admit Cards, & Schedules, Colleges & Universities news related to Admissions & Courses, Board exams, Scholarships, Careers, Education Events, New education policies & Regulations.

To get in touch with Shiksha news team, please write to us at news@shiksha.com

Call 8585951111

Call 8585951111

Comments