The Stress-Strain Curve is a way to graphically represent how a material behaves when force is applied to it. Stress and Strain are two important concepts that you will come across in Physic Class 11 chapter Mechanical Properties of Solids. Let’s simplify some of the concepts so that it’s easier to practice along with the NCERT Solutions for Chapter 8.

- What is Stress in the Stress-Strain Curve?

- What is Strain in Stress-Strain Curve?

- Hooke’s Law in Stress-Strain Curve

- Stress Strain Curve Explained

What is Stress in the Stress-Strain Curve?

Stress is the internal restoring force per unit area of a solid body.

In the Stress Strain Curve, we plot stress along the vertical axis.

What Causes Stress?

If you apply adequate force on a body that is in static equilibrium (when it doesn’t move at all), internal restoring forces develop within this body. That’s why there is stress.

Just a quick recap on internal restoring forces - It is a solid material’s way of being in it’s resting state, where the fundamental forces hold the matter together.

Formula for Calculating Stress

We calculate the magnitude of force with the formula

σ = F/A

Unit of Stress

The SI Unit of Stress is N m⁻² or pascal (Pa). Refer to why we use SI Units in the overview to Units and Measurements.

Types of Stress

There are different types of stress that you must know.

| Stress Type |

Description |

Direction of Force |

Effect on Material |

Example |

| Tensile Stress |

Material is pulled apart by opposing forces |

Perpendicular to cross-section (outward) |

Increases length |

Stretching a rubber band |

| Compressive Stress |

Material is squeezed by inward forces |

Perpendicular to cross-section (inward) |

Decreases length |

Column supporting building weight |

| Shearing Stress |

Material experiences parallel opposing forces |

Parallel to cross-sectional area |

Causes angular deformation |

Cutting with scissors, twisting motion |

| Hydraulic Stress |

Uniform pressure applied from all directions |

Perpendicular at all surface points |

Reduces volume, maintains shape |

Object submerged in deep water |

What is Strain in Stress-Strain Curve?

Strain is the aftereffect of stress. That is, it is the deformation of the solid object after enough force has caused it to bend or change its physical properties.

In the Stress Strain Curve, we have strain on the horizontal axis.

Formula (General Expression) of Strain

| Symbol |

Meaning |

| ε |

Strain (a measure of deformation) |

| δx |

Change in dimension (e.g., change in length, width, or volume) |

| x |

Original dimension (the starting measurement) |

Types of Strain

| Strain Type |

Corresponding Stress |

Definition |

Formula |

| Longitudinal Strain |

Longitudinal Stress |

Change in length divided by the original length |

Longitudinal Strain = ∆L / L |

| Shearing Strain |

Shearing Stress |

Relative displacement between opposite faces divided by the distance between them |

Shearing Strain = ∆x / L = tan θ |

| Volume Strain |

Hydraulic Stress |

Change in volume divided by the original volume |

Volume Strain = ∆V / V |

Hooke’s Law in Stress-Strain Curve

Before beginning with the Strain-Strain Curve, it’s essential to learn about Hooke’s Law.

Put simply, it says that stress is directly proportional to strain.

Formula for Hooke’s Law

Stress ∝ Strain, or Stress = k × Strain

k is the constant of proportionality. It’s called the modulus of elasticity.

Stress Strain Curve Explained

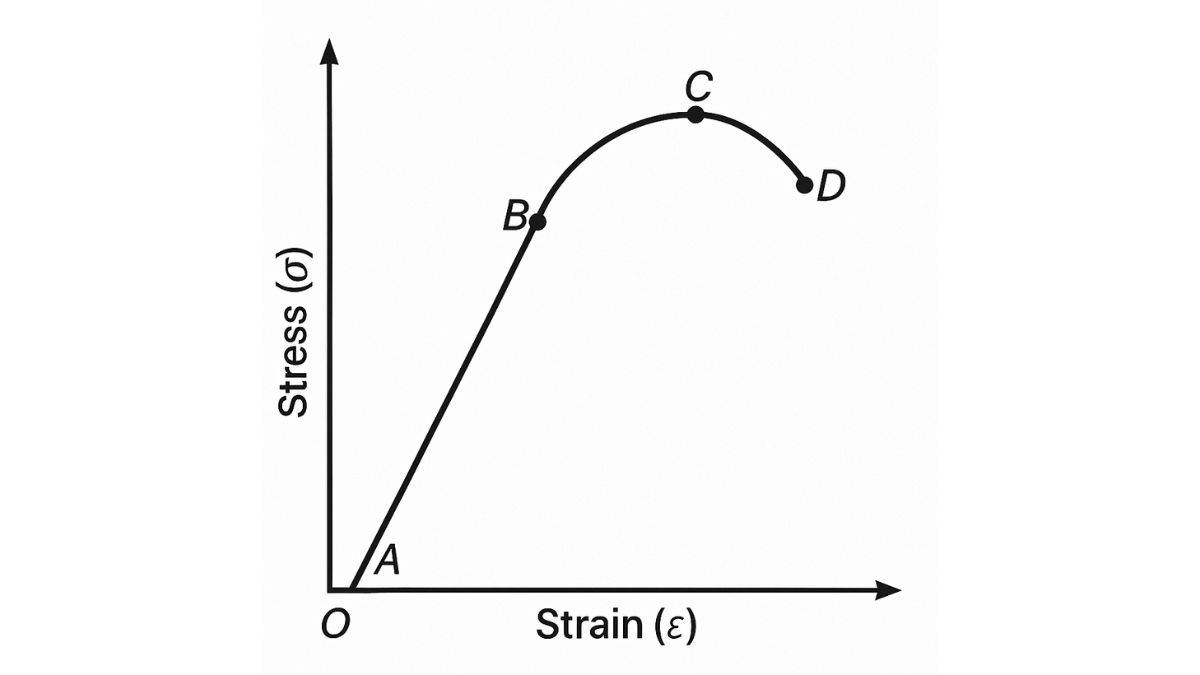

Let’s look at the stress-strain curve and the explanations below.

| Point |

Region |

Behaviour |

Reason for Behaviour |

| O–A |

Elastic (Hooke’s Law) |

Temporary deformation |

Atomic bonds stretch proportionally and can fully return to original state |

| A–B |

Nonlinear Elastic |

Still returns to original shape |

Bonds begin to experience slight non-linear stretching without breaking |

| B–C |

Plastic |

Permanent deformation starts |

Atomic bonds start breaking and reforming in new positions (dislocation motion) |

| C |

Ultimate Strength |

Max stress the material can bear |

Maximum resistance to stretching before internal weakening starts |

| D |

Fracture |

Material breaks |

Internal structure fails; cracks propagate until the material snaps |

Physics Mechanical Properties of Solids Exam

Student Forum

Other Class 11th Physics Chapters

- Physics Mechanical Properties of Solids

- NCERT Class 11 Physics

- NCERT Class 11 Notes

- NCERT Notes

- Physics Motion in Plane

- Physics Mechanical Properties of Fluids

- Physics Motion in Straight Line

- Physics System of Particles and Rotational Motion

- Physics Oscillations

- Physics Waves

- Physics Thermal Properties of Matter

- Physics Motion

- Physics Gravitation

- Physics Thermodynamics

- Physics Work, Energy and Power

- Physics Units and Measurement

- Physics Laws of Motion